Performed testing using this style of bulkhead and found a massive issue with its use that makes it extremely dangerous to use these as fuel bulkhead fittings. I notified STM of this issue on the phone when returning the items and on the return form. No follow up on their end. Video of test - https://www.youtube.com/watch?v=fKg7MBZ0zmw

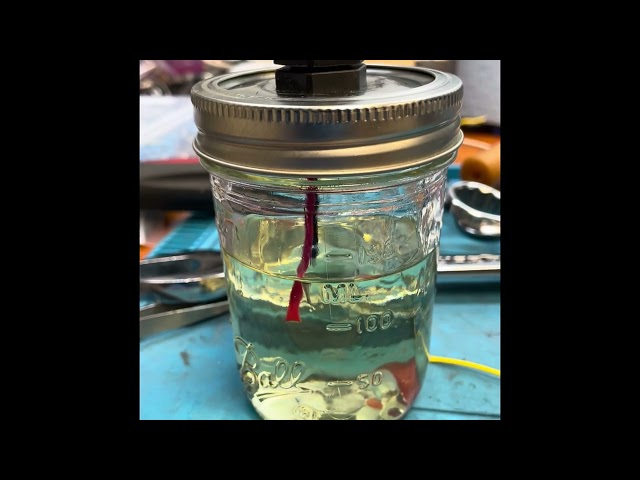

Testing done with fuel safe 14awg PTFE wire, sealed jar half full of gasoline.

The root cause of the issue is not necessarily the fitting itself, but that the fitting allows the wire to pass straight through. When the wire passes straight through, where one end is submerged in fuel and the other end is open, the wire will act as a straw. As the pressure in the fuel tank increases naturally from the fuel evaporating, the fuel will be forced up and out of the wires, traveling through the strands between the insulation. Same way a conventional spray gun works. Once the pressure inside the container is released then the "wicking" issue stops. Seeing as all fuel tanks/cells will always be under some pressure "higher than atmosphere" this issue will always occur. Correct method to prevent this is to not allow the wire to pass through, either by using some sort of hermetically sealed stud or connector.

From the video you can see that the red unsoldered wire is flowing fuel out and bubbling, this is the pressure from the evaporated fuel forcing itself out of the container through the wire. The black wire is soldered on both ends, this was a test to see if converting the multi strands into a single solid core stopped the "wicking" from occurring. While this did slow down the wicking issue a lot compared to the non-soldered wires, there was still fuel coming from the wire and you can see it slowly starting to form a drip.