Garrett G-Series Turbo G35-900

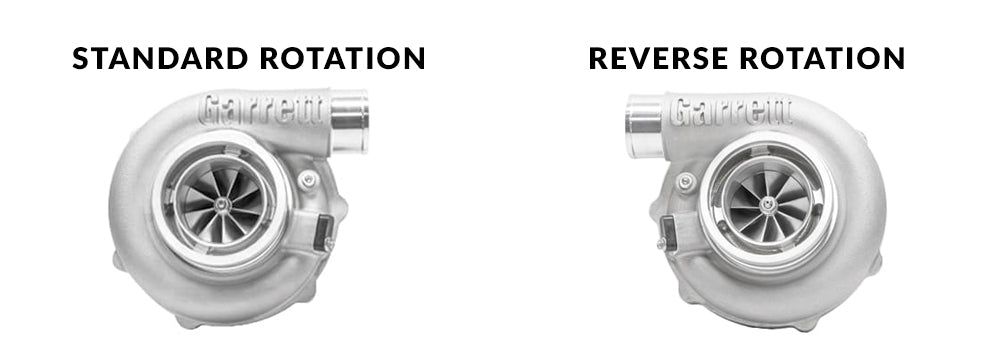

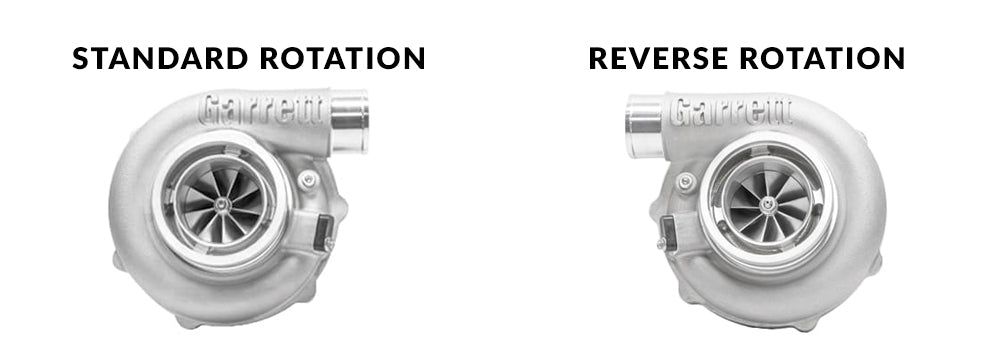

The G-Series G35-900 turbos are sold in a standard or reverse rotation design. You'll choose the Supercore, then choose the exhaust housing which will include matching clamps (and/or gaskets). Housings are available in T3, T4 divided and V-band (VB) configurations. Designed for use with an external wastegate.

To buy a full turbo, you'll need to add a Supercore and an Exhaust Housing to your cart. They are sold separately so you can replace just one side of your turbo if necessary. If you need any help, please give us a call!

Each Supercore and each Exhaust Housing Kit will be different depending on your selected options. The housings will include v-band clamps (and a gasket if choosing a T3 or T4 option). The Supercore includes no additional accessories. The standard rotation Supercore and 1.01 V-Band housing are pictured in detail for reference. The Supercore weighed in at 11.00 pounds and the housing at 11.90.

What flanges, fittings and clamps will I need for install?

Oil restrictor fittings are built-in to the turbo, you'll need a -4AN feed line. The water fittings are -6AN. Inlet and outlet flanges for building a manifold or downpipe, fittings and drain lines are listed in the table.

• Flange Dimensions PDF

Features:

• G-Series Compressor Aerodynamics for Maximum HP

• 62mm Turbocharger Compressor Wheel

• 77% Maximum Compressor Efficiency

• Mar-M Alloy Turbine Wheel Rated up to 1050°C

• New Turbine Aero Provides Higher Flow and Efficiency

• Stainless Steel Turbine Housings Rated up to 1050°C

• Oil Restrictor and Water Fittings Included

• Fully Machined Speed Sensor and Pressure Ports

• One Piece Center Housing with 360° Rotation (Non-Wastegated Only)

• Speed Sensor Port

Warning:

Maximum allowable turbocharger speed is 145krpm. The use of this product above max turbocharger speed is at the owner’s risk, and can result in damage and premature failure. To protect the turbocharger from overspeed when operating, a speed sensor can be installed into the compressor housing to monitor shaft speed.

Performance results of this product are highly dependent upon your vehicle’s modifications and tuning/calibration. The horsepower numbers represented are calculated based strictly on choke flow of the compressor map (total turbo capability), which represents the potential flywheel horsepower.

Speed Sensor Port:

The compressor housing features a fully machined ported shroud to help reduce compressor surge. A fully machined speed sensor port provides enthusiasts the option to add the new G Series speed sensor to measure turbocharger shaft speed, a key factor in determining ideal operating conditions.

The new speed sensor is easy to install and does not need to be adjusted for length like previous sensors. Simply remove and plug, then insert the speed sensor and tighten the bolt. The new speed sensor is sold separately and is not compatible with GT and GTX sensors due to the new design and sizing.

The addition of an o-ring between the compressor housing and backplate reduces the possibility of boost pressure leakage.

Speed Sensor Kits are sold separately:

• 781328-0003 or 781328-0004

The Most Powerful Mid-Frame Turbocharger Series on the Market:

Introducing performance out of a package you never thought possible. This clean sheet product is tailored to meet the demands of hard core racing enthusiasts while providing industry leading power capability in a small package.

The G-Series G35-900 turbocharger is compatible with 2.0L – 5.5L engine displacements and capable of producing up to 900 horsepower. G Series 35 turbochargers are highly efficient and will outflow all comparable products on the market.

New compressor and turbine aero combined with high temperature resistant materials allowed engineers to push the limits of performance.

A new name designates a new generation of industry leading technology and innovation.

Understanding the Name G35-900:

• G designates 81 years of Garrett® heritage

• 35 classifies the size of the frame

• The remaining 4 digits identify the max horsepower rating

Compressor Aero:

Forged fully-machined compressor wheel and new aerodynamics increase maximum horsepower output and boost response. The CFD (computational fluid dynamics) engineered compressor wheel increases air flow up to 15% for 60mm and 30% for 67mm with 79-80% efficiency. (Compared to GTX GenII)

Available in standard rotation and reverse rotation options for enthusiasts that want the perfect twin turbo installation or a single reverse rotation turbo for applications with installation restrictions.

Center Housing:

A new one-piece center housing and backplate increase durability and product safety by reducing the number of failure points associated with the turbocharger. The center housing to turbine housing v-band connection allows for 360 degree orientation when installing with Garrett® non-wastegated turbine housings.

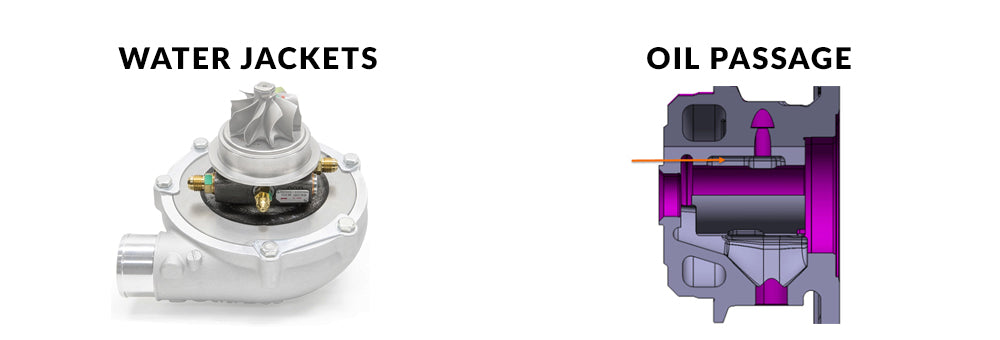

Water Jackets:

Four large water jacket ports increase cooling capacity and allow enthusiasts to customize water line routing to help improve the installation process. The turbocharger comes with two -6AN water fittings and two plugs.

*Recommended to install waterlines on opposite sides of the housing.

Oil Passage:

A single stage oil passage directs pressurized oil to the new oil cavity ensuring proper bearing lubrication at both sides of the cartridge.

Each turbocharger includes (1) -4AN oil restrictor fitting with a 1mm orifice to provide the turbo with the recommended 40psi of oil pressure.

Rotating Group – Twin Piston Rings:

A shorter bearing cartridge allows us to incorporate twin piston rings on both sides of the shaft wheel assembly. This will reduce the likeliness of oil leakage at the seals from the center housing to the compressor and or turbine stage.

Turbine Wheel Aero:

The turbine wheel features all new aerodynamics to improve flow and boost response. The new turbine wheel is made of Mar-M super alloy and is capable of handling exhaust gas temperatures up to 1050 degrees C.

The new turbine wheel flows 15-20% more than GTX and has peak efficiency of 74%.

Turbine Housings:

All G Series Turbine housings are made from stainless steel to provide ultimate durability and temperature resistance up 1050 degrees C.

Internally wastegated housings are compact, efficient, and designed with maximum bypass port size to reduce boost creep and provide better boost control.

Turbine housings are available in a variety of open volute Vband configurations so be sure to order the correct part for your application.

To buy a full turbo, you'll need to add a Supercore and an Exhaust Housing to your cart. They are sold separately so you can replace just one side of your turbo if necessary. If you need any help, please give us a call!

Each Supercore and each Exhaust Housing Kit will be different depending on your selected options. The housings will include v-band clamps (and a gasket if choosing a T3 or T4 option). The Supercore includes no additional accessories. The standard rotation Supercore and 1.01 V-Band housing are pictured in detail for reference. The Supercore weighed in at 11.00 pounds and the housing at 11.90.

| Supercore PN | Rotation | Supercore Specs | Supercore Install Parts & Notes | ||||

| 880695‑5001S | Standard | Compressor: (0.72 A/R) • 65 Trim • 62mm Inducer • 76mm Exducer Turbine: • 84 Trim • 68mm Inducer • 62mm Exducer |

• Oil Outlet Flange STM -10AN GT-Series • Oil Feed Fitting: -4AN • Water Fittings: -6AN • Compressor Outlet: 2" Coupler • Compressor Inlet: 4" Coupler |

||||

| 880696‑5001S | Reverse | ||||||

| Housing Kit PN | Rotation | Housing Specs | Housing Install Parts & Notes | ||||

| A/R | Inlet | Outlet | Inlet | Outlet | |||

| 740902-0108 | Standard | 1.06 | T4 | VB |

• T4 Divided Inlet Flange: Vibrant (1442 or 14420) • T4 Divided Inlet Gasket: Vibrant (1442G) |

• V-Band Outlet Flange: Vibrant (19886) • V-Band Outlet Clamp: Vibrant (1415C) |

|

| N/A | Reverse | ||||||

| 740902-0106 | Standard | 0.83 | T3 | VB |

• T3 Inlet Flange: Vibrant (1431 or 14310) • T3 Inlet Gasket: STM Stainless |

||

| 740902-0116 | Reverse | ||||||

| 740902-0107 | Standard | 1.01 | T3 | VB | |||

| 740902-0117 | Reverse | ||||||

| 740902-0102 | Standard | 0.61 | VB | VB |

• V-Band Inlet Flange: Vibrant (1390) • V-Band Inlet Clamp: Vibrant (1416C) |

||

| 740902-0112 | Reverse | ||||||

| 740902-0103 | Standard | 0.83 | VB | VB | |||

| 740902-0113 | Reverse | ||||||

| 740902-0104 | Standard | 1.01 | VB | VB | |||

| 740902-0114 | Reverse | ||||||

| 740902-0105 | Standard | 1.21 | VB | VB | |||

| 740902-0115 | Reverse | ||||||

Oil restrictor fittings are built-in to the turbo, you'll need a -4AN feed line. The water fittings are -6AN. Inlet and outlet flanges for building a manifold or downpipe, fittings and drain lines are listed in the table.

• Flange Dimensions PDF

Features:

• G-Series Compressor Aerodynamics for Maximum HP

• 62mm Turbocharger Compressor Wheel

• 77% Maximum Compressor Efficiency

• Mar-M Alloy Turbine Wheel Rated up to 1050°C

• New Turbine Aero Provides Higher Flow and Efficiency

• Stainless Steel Turbine Housings Rated up to 1050°C

• Oil Restrictor and Water Fittings Included

• Fully Machined Speed Sensor and Pressure Ports

• One Piece Center Housing with 360° Rotation (Non-Wastegated Only)

• Speed Sensor Port

Warning:

Maximum allowable turbocharger speed is 145krpm. The use of this product above max turbocharger speed is at the owner’s risk, and can result in damage and premature failure. To protect the turbocharger from overspeed when operating, a speed sensor can be installed into the compressor housing to monitor shaft speed.

Performance results of this product are highly dependent upon your vehicle’s modifications and tuning/calibration. The horsepower numbers represented are calculated based strictly on choke flow of the compressor map (total turbo capability), which represents the potential flywheel horsepower.

Speed Sensor Port:

The compressor housing features a fully machined ported shroud to help reduce compressor surge. A fully machined speed sensor port provides enthusiasts the option to add the new G Series speed sensor to measure turbocharger shaft speed, a key factor in determining ideal operating conditions.

The new speed sensor is easy to install and does not need to be adjusted for length like previous sensors. Simply remove and plug, then insert the speed sensor and tighten the bolt. The new speed sensor is sold separately and is not compatible with GT and GTX sensors due to the new design and sizing.

The addition of an o-ring between the compressor housing and backplate reduces the possibility of boost pressure leakage.

Speed Sensor Kits are sold separately:

• 781328-0003 or 781328-0004

The Most Powerful Mid-Frame Turbocharger Series on the Market:

Introducing performance out of a package you never thought possible. This clean sheet product is tailored to meet the demands of hard core racing enthusiasts while providing industry leading power capability in a small package.

The G-Series G35-900 turbocharger is compatible with 2.0L – 5.5L engine displacements and capable of producing up to 900 horsepower. G Series 35 turbochargers are highly efficient and will outflow all comparable products on the market.

New compressor and turbine aero combined with high temperature resistant materials allowed engineers to push the limits of performance.

A new name designates a new generation of industry leading technology and innovation.

Understanding the Name G35-900:

• G designates 81 years of Garrett® heritage

• 35 classifies the size of the frame

• The remaining 4 digits identify the max horsepower rating

Compressor Aero:

Forged fully-machined compressor wheel and new aerodynamics increase maximum horsepower output and boost response. The CFD (computational fluid dynamics) engineered compressor wheel increases air flow up to 15% for 60mm and 30% for 67mm with 79-80% efficiency. (Compared to GTX GenII)

Available in standard rotation and reverse rotation options for enthusiasts that want the perfect twin turbo installation or a single reverse rotation turbo for applications with installation restrictions.

Center Housing:

A new one-piece center housing and backplate increase durability and product safety by reducing the number of failure points associated with the turbocharger. The center housing to turbine housing v-band connection allows for 360 degree orientation when installing with Garrett® non-wastegated turbine housings.

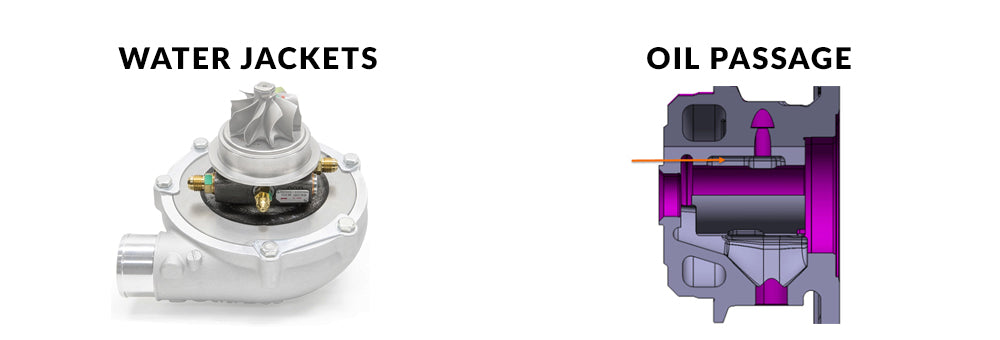

Water Jackets:

Four large water jacket ports increase cooling capacity and allow enthusiasts to customize water line routing to help improve the installation process. The turbocharger comes with two -6AN water fittings and two plugs.

*Recommended to install waterlines on opposite sides of the housing.

Oil Passage:

A single stage oil passage directs pressurized oil to the new oil cavity ensuring proper bearing lubrication at both sides of the cartridge.

Each turbocharger includes (1) -4AN oil restrictor fitting with a 1mm orifice to provide the turbo with the recommended 40psi of oil pressure.

Rotating Group – Twin Piston Rings:

A shorter bearing cartridge allows us to incorporate twin piston rings on both sides of the shaft wheel assembly. This will reduce the likeliness of oil leakage at the seals from the center housing to the compressor and or turbine stage.

Turbine Wheel Aero:

The turbine wheel features all new aerodynamics to improve flow and boost response. The new turbine wheel is made of Mar-M super alloy and is capable of handling exhaust gas temperatures up to 1050 degrees C.

The new turbine wheel flows 15-20% more than GTX and has peak efficiency of 74%.

Turbine Housings:

All G Series Turbine housings are made from stainless steel to provide ultimate durability and temperature resistance up 1050 degrees C.

Internally wastegated housings are compact, efficient, and designed with maximum bypass port size to reduce boost creep and provide better boost control.

Turbine housings are available in a variety of open volute Vband configurations so be sure to order the correct part for your application.

See more Garrett Products

|

WARNING: Cancer and Reproductive Harm www.p65warnings.ca.gov |